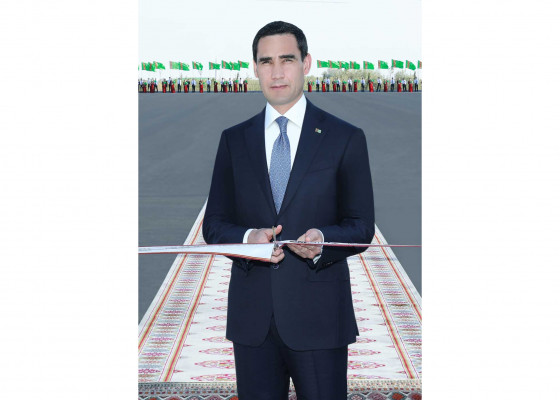

On 8 September 2025, a new glass production workshop was inaugurated at an industrial complex in the northern part of Ashgabat. President Serdar Berdimuhamedov led the opening ceremony.

The facility is equipped with high-tech equipment from leading global manufacturers, incorporating automated control and quality assurance systems to ensure that the produced goods meet international standards.

The project was implemented with adherence to international environmental standards. Advanced systems for managing production waste have been introduced to prevent soil and water pollution. Additionally, innovative solutions for optimizing gas and energy consumption enhance energy efficiency, reduce costs, and increase the competitiveness of the production process.

The facility’s capacity is sufficient to fully meet domestic market demands while also enabling the export of products. Turkmenistan’s strategic location at the intersection of international transport corridors plays a key role in realizing the export potential, simplifying logistics, reducing transportation costs, and enhancing competitiveness in international markets.

The new production facility will also contribute to the development of other sectors of the national economy by meeting the needs of the food and pharmaceutical industries for high-quality glass containers, thereby reducing production costs and improving product quality.

The workshop will provide hundreds of jobs for the local population.

Production Process

President Berdimuhamedov visited the facility’s laboratory, which is equipped with cutting-edge equipment from leading global companies. Notably, the BTLT-2 device tests the resistance of bottles to vertical compression, the Vici Vision device performs automated geometric measurements, the Labniks device tests hydrostatic compression, and the AGR device assesses resistance to abrasion and other damage. These ensure the high quality of the products.

The President then proceeded to the production workshop, where he observed the technological process. It begins with melting raw materials—consisting of local quartz sand, limestone, dolomite, and other additives—in a furnace at high temperatures reaching 1,500 degrees Celsius.

The molten glass is then fed into an IS machine, where glass products of various sizes are formed through blowing. The products are subsequently transferred to annealing furnaces for cooling.

Finished products pass through an automated quality control line equipped with cameras and sensors. They are then sent to an automatic packaging line before being stored in warehouses for distribution to consumers.

International Certifications

The workshop was awarded several certificates by companies involved in the project:

– A certificate confirming that the installed equipment meets international quality standards, particularly those in Germany, from Horn Glass Industries.

– A certificate verifying that the workshop’s technological equipment complies with international standards for quality, environmental management, and safety, from Vetromeccanica Srl (Italy).

– A certificate for the implementation of an integrated management system meeting international standards, from Bottero (Italy).